- Read the PTS

a. Scope

of work

b. Number

of panels

c.

Additional card for SCADA, SOE, Annu, DFR

- Site Visit

1. Collect

all IFC drawings from existing station

2. Collect

all existing point list

3. Check

cable rote length for fiber & control cables & Power cables

- Materials

1. Check

the availability of all Control & Power & Fiber optic cables and cable hose

2. Check

Ferule Machine and tap

3. Check

Lugs

4. Check

panels and find the missing materials before outage

5. Check

the loose materials

6. Check

all communication materials ( Optif , SFT ect)

- Point list

SAS, SACDA, SOE, Annu, DFR

1. Check

all New point list IFC

2. Before

Outage, discuss with SCADA deportment for using the spare points through PMD

3. Submit

the RFI and Point list to SCDA deportment soft & Hard copy and conform the

witness.

4. Check

SAS engineer Iquma & He should be direct employ of the company otherwise

SAS Vendor should give the letter with proper note pad and stamp ( Strict order

from SCADA deportment ) .

5. Don’t

do existing Measurement points, Transducer will make issue.

6. After

open loop submit the points to SCADA & PCC for SAS close loop or SCADA

final commissioning

7. Conform

the PCC witness & SCADA witness & SCADA vendor for final commissioning.

- Vendor follow

ups

1. Check

the PO for all Vendors

2. Send

mail for vendors SAS , SCADA, SOE, DFR and Fault locator , AMI , Fiber optic

testing team.

3. Check

SEC ID

4. Collect

Iqama copy from vendor

5. Collect

all PO copies for Temporary access.

6. Collect

laptop details for Temporary access.

- Testing activities

1. Don’t touch the Protection panels without

getting permission from PCC

2. Whenever

touch existing panel inform PED.

3. Testing

agency engineer SEC ID , Testing Approval

4. Testing Team - Panel wiring , Relay

configuration, Aux relays , Schemes

5. First

time CSD 3 week schedule send through PMD

6. Get

the signature in all drawings CSD &

Testing engineers

7. LCC

access make LOA for GIS witness

8. Tripping

test make separate LOA

9. SCADA

& SAS Make separate LOA

10. CSD

– Pre commissioning check list should be fill

11. Reserve

the Testing engineers & SAS engineers for commissioning activity

7. Communication

1.

Send Channel request for Fault Locator & AMI & PSE Differential

protection with SLD & Communication drawing

2.

Coordinate with NEC or ABB for get updated communication drawing and

communication link

3.

Coordinate with NEC or ABB for Optif card installation check SFP converter its

dB range (If applicable).

4.

Apply communication accesses and follow with communication deportment and make

communication LOA with approved access.

5. Laying

Fiber , RJ45, Bueldon cable.

6. 2

Mpbs Micom 546 need Baloon converter and coaxial cable .

7. Proper

soldering need for coaxial cable and cable connector to avoid differential

communication fail.

8. Check

all cables, orange hose , cable rote , cable rope for tie, small boot lugs ,

channel allocation table from NEC, communication drawings, LOA approved copy,

communication access copy.

9. Include

Fiber optic testing in the communication LOA.

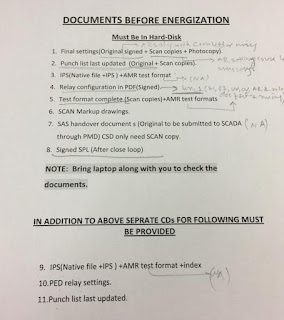

8. Documents submission

- Submit one soft

copy CD to PMD & P TD

- Submit one soft

copy HARD DISC to CSD

- Updated point list

to SCADA

- All documents

submit through proper submittal with Delivery Note