Saturday, July 30, 2016

Wednesday, July 27, 2016

Winding Resistance Issue in 67 MVA Transformer

The winding resistance Measurement of the Transformer most impotent test because

1. To find out the week part and break down in the winding

2. To find out the Bolt tightness and connection shoes gripping

Normally winding resistance measured between

1. Phase to Phase in Delta & Star connection

RY , YB, BR

2. Phase to neutral in Star connection

RN, YN, BN

This site test result will be compared with factory test result and the error should be less than ≤ 5%

Issue in site Test Result

Transformer Rating

67 MVA ,

115/13.8 kV

Dyn1 three winding Transformer

During site test the LV side winding resistance as below

As per site test result R phase winding resistance is high.

The result was sent to factory and factory suggested to clean the surface and meassure value again with 10 DC volt.

The Transformer winding resistance again measured with Omicron CPC 100 .

The inject current ratings of the kit are 2A, 6A, 400A.

So 6A was injected for measurement and the results are same.

Measured value 7.577 mΩ at 75 ⁰c and FAT value 6.874 mΩ at 75 ⁰c error value is -10% and it should be ≤ -5%. ( Test report attached )

Minimum current is enough for measure the resistance. 2A current was injected and result was same.

But minimum current will take more time to stable the reading (resistance value).

Problem Analysis and Rectification

Factory testing engineers came to site.

After complete all rectification process winding resistance was measured and result found was with in the limit. 5.533m ohms

1. To find out the week part and break down in the winding

2. To find out the Bolt tightness and connection shoes gripping

Normally winding resistance measured between

1. Phase to Phase in Delta & Star connection

RY , YB, BR

2. Phase to neutral in Star connection

RN, YN, BN

This site test result will be compared with factory test result and the error should be less than ≤ 5%

Issue in site Test Result

Transformer Rating

67 MVA ,

115/13.8 kV

Dyn1 three winding Transformer

During site test the LV side winding resistance as below

| PHASE | SITE RESULT AT 30⁰ C | SITE RESULT AT 75⁰ | FAT RESULT AT 75⁰ C | ERROR |

| RN | 6.599 mΩ | 7.577 mΩ | 6.872 mΩ | ≥ 10% |

| YN | 5.788 mΩ | 6.646 mΩ | 6.674 mΩ | ≤ 5% |

| BN | 5.752 mΩ | 6.604 mΩ | 6.6322 mΩ | ≤ 5% |

| RY | 12.18 mΩ | 13.99 mΩ | 13.36 mΩ | ≤ 5% |

| YB | 11.38 mΩ | 13.07 mΩ | 13.125 mΩ | ≥ 10% |

| BR | 12.19 mΩ | 13.99 mΩ | 13.323 mΩ | ≤ 5% |

As per site test result R phase winding resistance is high.

The result was sent to factory and factory suggested to clean the surface and meassure value again with 10 DC volt.

The Transformer winding resistance again measured with Omicron CPC 100 .

The inject current ratings of the kit are 2A, 6A, 400A.

So 6A was injected for measurement and the results are same.

Measured value 7.577 mΩ at 75 ⁰c and FAT value 6.874 mΩ at 75 ⁰c error value is -10% and it should be ≤ -5%. ( Test report attached )

Manufacturer suggested 10A dc but in equipment there is no option

for that value.

The winding resistance will not vary with injected current.

Because winding resistance is very low in terms of mΩ.

The winding resistance will not vary with injected current.

Because winding resistance is very low in terms of mΩ.

Minimum current is enough for measure the resistance. 2A current was injected and result was same.

But minimum current will take more time to stable the reading (resistance value).

Problem Analysis and Rectification

Factory testing engineers came to site.

Factory Action -1

Factory Action - 2

After complete all rectification process winding resistance was measured and result found was with in the limit. 5.533m ohms

Tuesday, July 26, 2016

RED 670 Differential current

There is a issue raised during differential stability in End to End test.

1. 1 1/2 scheme there are two CTs are connected in RED 670 relay

2. 1 amps with 0 dec injected in one CT and 1 amps with 180 dec injected in other CT

3. Now the Differential current IDL1MAG , IDL2MAG , IDL3MAG in three phase should be zero.

4. But there is small primary current read in all three phases around 100Amps in both source end and remote end relays.

5. Engineers tried to solve but not.

6. Then the line was energized and differential current got normal around zero.

Differential reading after energize the line

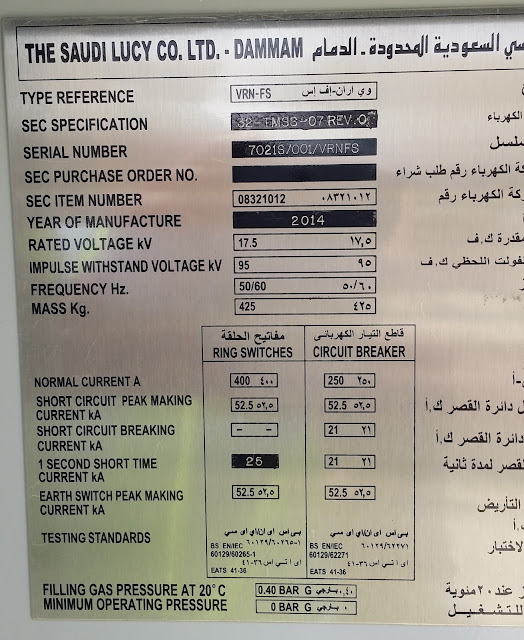

Distribution RMU

At the same time Station distribution supply can take for out side distribution through RMU.

RMU

Relay Setting

Back side cable cover interlock with Earth Switch

RMU -2

Thursday, July 14, 2016

380/230/115/13.8 kV Sub Station Energized

Doha BSP 380/230/115/13.8 kV Sub Station Energized on 23.06.2016 successfully. I really appreciate all Engineering and technicians who's hardly working for achieve the target.

The points should consider before Energization

1. Checks the all transformer and Air busing for temporary earthing.

2. Rack in all MCAG and MFAG relays

3. Close all FTs in the protection panels

4. Check all CB trip circuit supervision relays

5. Check all alrams in the SAS monitor and clear unwanted

6. Take 10 copies of Single line diagram.

7. Check all Secondary VT TBs in LCC and VT MCBs in VT Terminal BOX.

8. Check all CT connections in Metrosil & Resistor

9. Check operation off all equipments ( CB, DS ES , RTCC) final kept all equipment in open condition and put LOCAL/REMOTE switch in REMOTE position.

10. The BB block alarm will appear if CB in test position.

11. Keep all Transformer in lower TAP position ( Lowest voltage)

12. All Surge arrestor shorting link in open position

13. Some times Line Zone -2 time setting will be instantaneous ( If recommended)

14. Check Syn function in all LL-LB LL-DB DL - DB combination ( If possible)

15. Check the Gas levels in Gas monitor and keep GIS gas cylinder and filling machine for back up

16. Open all panels and check IN/OUT switch , open wires, CT VT TBs , all wires should away from the Panel Heater and temporary shorting.

17. Conform the availability of Phase Sequence meter and Multi meter with length leads , and clam meter.

18. Conform Temporary Final setting for Spare bays ( Stub or Over current )

19. Keep all ACDCs in Auto mode .

The points should consider before Energization

1. Checks the all transformer and Air busing for temporary earthing.

2. Rack in all MCAG and MFAG relays

3. Close all FTs in the protection panels

4. Check all CB trip circuit supervision relays

5. Check all alrams in the SAS monitor and clear unwanted

6. Take 10 copies of Single line diagram.

7. Check all Secondary VT TBs in LCC and VT MCBs in VT Terminal BOX.

8. Check all CT connections in Metrosil & Resistor

9. Check operation off all equipments ( CB, DS ES , RTCC) final kept all equipment in open condition and put LOCAL/REMOTE switch in REMOTE position.

10. The BB block alarm will appear if CB in test position.

11. Keep all Transformer in lower TAP position ( Lowest voltage)

12. All Surge arrestor shorting link in open position

13. Some times Line Zone -2 time setting will be instantaneous ( If recommended)

14. Check Syn function in all LL-LB LL-DB DL - DB combination ( If possible)

15. Check the Gas levels in Gas monitor and keep GIS gas cylinder and filling machine for back up

16. Open all panels and check IN/OUT switch , open wires, CT VT TBs , all wires should away from the Panel Heater and temporary shorting.

17. Conform the availability of Phase Sequence meter and Multi meter with length leads , and clam meter.

18. Conform Temporary Final setting for Spare bays ( Stub or Over current )

19. Keep all ACDCs in Auto mode .

SEIMENS Ethernet switch

We are used RUGGEDCOM RSG2100NC SEIMENS Ethernet switch was used for SAS net work.

There are two Power supply unit in the switch.

Due to Over Temperature or DC fluctuating or some other reason one unit was fail nearly 15 nos.

The power unit was changed in the site.

There are two Power supply unit in the switch.

Due to Over Temperature or DC fluctuating or some other reason one unit was fail nearly 15 nos.

The power unit was changed in the site.

Power Module

|

Extra port added in the switch

Subscribe to:

Comments (Atom)